In December 2018, Q&D Construction, based in Sparks, NV, contracted Advanced Marine to provide underwater support services to repair the 100+ year old Fleish Hydroelectric facility, located on the Truckee River in Verdi, NV. The facility is owned and operated by the Truckee Meadows Water Authority.

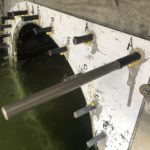

In late 2018, TMWA staff discovered one of the 50 inch diameter draft tubes that exhaust water from the hydroelectric Pelton wheel had separated from the building and fallen into the after bay. This caused an imbalance on the Pelton wheel bearings, creating a significant maintenance issue.

The project was originally scheduled to start in early January. Due to winter weather delays, Advanced Marine mobilized to the site in February, 2019 during snowy conditions. The work scope included removal of the old existing draft tubes, patching the concrete face where the draft tubes exited the hydro building, installing nearly eighty (80) 1 inch diameter stainless steel anchor rods, most with an embedment of 20 inches, and installing the two new draft tubes.

Facing logistical issues working in the Truckee River during freezing conditions, Advanced Marine divers set to work. After removing the old draft tubes, divers discovered scoured voids beneath the pipes extending up to 4 feet inside the building foundation. Additionally, the old pipes had torn off inside the face of the wall. This would require additional steel repair work to restore the tubes inside the foundation to provide a proper mating surface for the new tubes. Working with the TMWA project engineers, Advanced Marine developed a plan to form and pressure grout a new wall.

“The 100-year old concrete presented some challenges for us”, said Advanced Marine president John Shaw. “The old concrete was extremely hard. Additionally, the large aggregate in the old concrete created a rough surface to which it was impossible to set our form. We had to hand place underwater repair mortar to create the desired smooth sealing surface. Our divers spent about two weeks chipping concrete under water in preparation for the wall.”

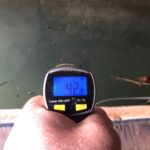

River water levels were rising rapidly. Water temperatures ranged from 38-45 degrees. Once the concrete surface had been prepared, the divers had to template a concrete form to match the rough contours of the arch surrounding the draft tube area. Special care and accuracy was required to seal to the edges of the old pipes and avoid blowing out the concrete form.

“The new draft tube design also presented some significant challenges”, according to Shaw. The mating flanges were fabricated using 1-1/8 steel plate. The flange holes were drilled to 1-1/4 inches. This meant 1/8 inch clearance all around through which to stab thirty-eight (38) anchor rods. “The holes had to be drilled nearly perfectly and the new epoxy anchors installed straight”, said Shaw. “Any deviation would likely result in a costly failure during the new draft tube installation process.”

Working closely with the Truckee Meadows Water Authority and contracted project engineers, systems and processes were designed and implemented to overcome each challenge. While the project took a little longer than anticipated, the Utility was pleased with the result. “Our primary goal is always to provide a quality product that meets or exceeds the customer’s expectations”, said Shaw. “I believe we successfully achieved that goal here.”

With about seventy (70) work days on site, Advanced Marine successfully installed the new draft tubes on the first attempt and restored the hydroelectric facility to full operation.